We manufacture a wide range of active ingredients and functionals

Our strong pharmaceutical heritage & health expertise allows us to provide:

- Strong expertise in synthesis from simple to complex molecules

- Strict respect of quality, global compliance, and environmental regulations

- Versatile R&D and large production capacities for new development and scale up activities

- FLAGSHIP technologies (flow chemistry, multi-catalysis, fractionated distillation)

SEQENS is a company committed to a CSR approach for over 15 years(Gold & Platinum EcoVvadis certifications)

Key figures

200+

employees

2

dedicated sites

5

shared sites

300+

customers

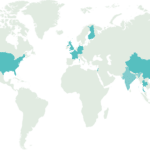

30+

countries